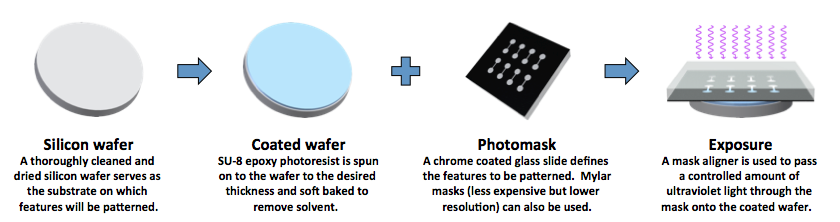

PDMS Microfluidics Fabrication

Microfluidic devices allow for precise control of very small quantities of fluid. They find widespread use in lab-on-a-chip devices, in which precisely defined sample volumes must be mixed and directed to various analysis chambers.

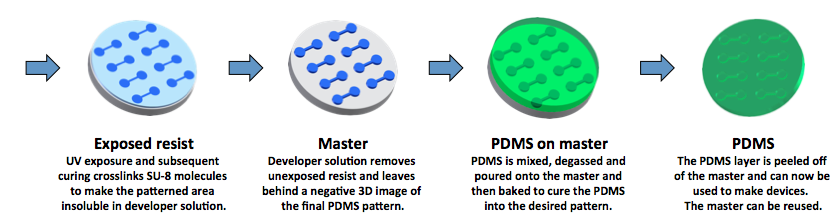

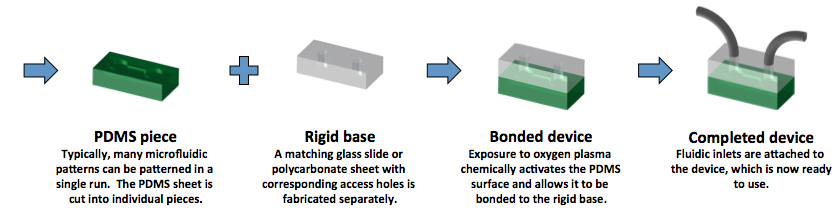

The fluidic channels in a microfluidic device are molded into a layer of polydimethylsiloxane (PDMS), a transparent biocompatible polymer. Molding is accomplished by pouring uncured PDMS onto a prepatterned master, on which an epoxy-based photoresist (SU-8) has been used to define features as small as 1μm. The process shown below can be used for inexpensive, rapid prototyping of microfluidic devices in our facilities here at UCSC.